Copper

Copper is a highly versatile and widely used metal known for its excellent conductivity, corrosion resistance, and attractive appearance. It is a reddish-brown metal with a characteristic metallic luster. Copper is one of the oldest known metals used by humans, and its applications span across various industries and everyday objects.

One of the standout properties of copper is its exceptional electrical and thermal conductivity. It is among the best conductors of electricity, making it ideal for electrical wiring, power transmission, and electronic components. Copper’s high thermal conductivity also makes it suitable for heat sinks, radiators, and various heat transfer applications.

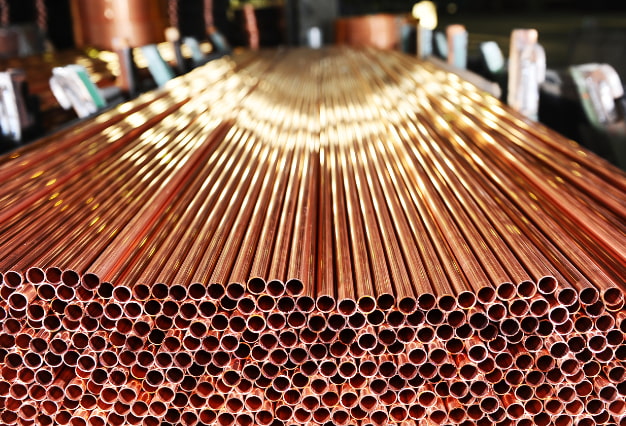

Copper is highly ductile and malleable, meaning it can be easily shaped and formed without losing its structural integrity.

This property allows for the production of intricate designs and complex shapes in industries such as architecture, sculpture, and decorative art. Copper’s malleability also enables it to be drawn into thin wires, making it crucial for applications like electrical cables and wiring.

Another important characteristic of copper is its corrosion resistance. It forms a protective layer called a patina when exposed to air and moisture, which prevents further corrosion. This property makes copper highly durable and long-lasting, particularly in outdoor applications such as roofing, gutters, and outdoor sculptures.

Copper is widely used in plumbing systems due to its antimicrobial properties. It naturally inhibits the growth of bacteria, viruses, and fungi, making it suitable for water supply pipes, fittings, and medical equipment. Copper’s antimicrobial nature also finds applications in food processing, brewing, and healthcare settings.

Beyond its functional properties, copper’s warm reddish-brown color and aesthetic appeal make it a sought-after material for architectural accents, interior design elements, and artistic creations. It is often used for decorative features, jewelry, coins, and fine craftsmanship.

Copper is also a crucial component in various industrial sectors. It is used in electrical and electronic devices, such as motors, generators, transformers, and printed circuit boards. The metal is essential in manufacturing industries like automotive, aerospace, telecommunications, and renewable energy systems.

Key Features of Copper

High thermal and electrical conductivity: Copper is one of the best conductors of heat and electricity, making it ideal for use in wires and other electrical applications.

Strength and durability: Copper is a strong and durable metal that can withstand a wide range of environmental conditions.

Corrosion resistance: Copper is resistant to corrosion, making it a good choice for use in applications where exposure to water or other chemicals is likely.

Ductility and malleability: Copper is a ductile and malleable metal, making it easy to shape and form.

Aesthetics: Copper has a warm, reddish-orange color that is often used in decorative applications.

Antimicrobial properties: Copper has antimicrobial properties, meaning that it can kill bacteria and viruses. This makes it a potential candidate for use in medical applications.

Applications

Copper is the most widely used metal for electrical conductors. It is used in a variety of electrical applications, including wires, cables, and busbars. Copper is used in electrical applications because it is a good conductor of electricity and heat.

Copper is used in a variety of construction applications, including roofing, plumbing, and wiring. Copper is used in construction applications because it is a strong and durable metal that is resistant to corrosion.

Copper is used in a variety of manufacturing applications, including electronics, machinery, and transportation. Copper is used in manufacturing applications because it is a good conductor of electricity and heat, and it is also a relatively inexpensive metal.

Copper is used in a variety of aesthetic applications, such as roofing, jewellery, and cookware. Copper is used in aesthetic applications because it is a beautiful metal with a warm, reddish-orange colour.

Copper has antimicrobial properties, meaning that it can kill bacteria and viruses. This makes it a potential candidate for use in medical applications, such as wound dressings and surgical instruments.

Grades of Copper

- Oxygen-Free High Conductivity (OFHC) Copper:

Composition: OFHC copper has a minimum copper content of 99.95% and very low levels of impurities.

Properties: It has the highest electrical conductivity among copper grades, making it ideal for electrical and electronic applications that require exceptional conductivity and minimal signal loss. OFHC copper is often used in power transmission, electrical wiring, and high-performance electronic devices.

- Electrolytic Tough Pitch (ETP) Copper:

Composition: ETP copper has a minimum copper content of 99.90% and may contain small amounts of oxygen, phosphorus, and other impurities.

Properties: It exhibits excellent electrical and thermal conductivity, good corrosion resistance, and high ductility. ETP copper is commonly used in electrical conductors, transformers, heat exchangers, and plumbing applications.

- Deoxidized High Phosphorus (DHP) Copper:

Composition: DHP copper contains a small percentage of phosphorus, usually around 0.01-0.04%.

Properties: DHP copper offers good electrical and thermal conductivity, along with enhanced corrosion resistance compared to ETP copper. It is often used in plumbing systems, heat exchangers, and other applications that require improved resistance to dezincification.

- Phosphor Bronze:

Composition: Phosphor bronze is an alloy of copper with varying amounts of tin and phosphorus. The typical composition ranges from 5-10% tin and 0.01-0.35% phosphorus.

Properties: Phosphor bronze exhibits excellent corrosion resistance, high strength, and good fatigue resistance. It is commonly used in applications such as electrical connectors, springs, fasteners, and musical instruments.

- Beryllium Copper:

Composition: Beryllium copper is an alloy of copper with a small percentage of beryllium, typically ranging from 0.5-2.75%.

Properties: Beryllium copper offers high strength, excellent electrical and thermal conductivity, and good corrosion resistance. It also possesses exceptional spring properties, wear resistance, and non-magnetic properties. Beryllium copper is often used in connectors, switches, electrical contacts, and specialized tools.

Lead

Lead is a heavy, bluish-gray metal that is known for its dense and malleable properties. It has been used by humans for thousands of years due to its abundance and various useful characteristics. However, it is important to note that lead is a toxic substance and proper precautions must be taken to prevent exposure and contamination.

One of the primary properties of lead is its high density, which makes it one of the heaviest common metals. This density contributes to its effectiveness as a shielding material against radiation and as a weight in various applications, such as in counterweights or ballasts.

Lead is also highly malleable, meaning it can be easily shaped or formed without breaking. It can be flattened into thin sheets, rolled into wires, or molded into intricate shapes. This malleability allows lead to be used in applications where it needs to conform to specific designs or fit into tight spaces.

Another characteristic of lead is its resistance to corrosion. It forms a protective layer on its surface when exposed to air, known as a patina, which helps slow down further oxidation. This corrosion resistance makes lead suitable for certain applications in environments where other metals would degrade or corrode.

Applications

Lead-acid batteries, commonly used in vehicles, are one of the major applications of lead. The lead acts as an electrode and sulfuric acid as the electrolyte in these batteries.

The high density of lead makes it an effective material for shielding against radiation in medical and nuclear applications. It is used in X-ray rooms, radiation therapy facilities, and nuclear power plants to protect individuals from harmful radiation.

Lead has been historically used in construction for roofing, flashing, and gutter systems due to its durability and resistance to corrosion. It has also been used for pipes and plumbing fixtures, although its use in plumbing has decreased due to health concerns.

Lead has been used in the manufacturing of bullets and ammunition due to its high density and malleability. However, there is an increasing shift towards non-toxic alternatives in certain regions due to environmental and health concerns.

Lead is used in certain electrical cables and wires as a sheathing material. Its malleability allows it to be easily formed around the conductive wires, providing protection and insulation.

Lead has been widely used in soldering applications due to its low melting point and ability to bond with other metals. It is also used as an alloying element in various metal alloys, such as brass and bronze, to enhance specific properties.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

Tin

Tin is a lustrous, silvery-white metal known for its low toxicity, malleability, and corrosion resistance. It has been used by humans for thousands of years, primarily due to its desirable properties and versatile applications.

One of the defining characteristics of tin is its low melting point. With a melting point of 231.9 degrees Celsius (449.4 degrees Fahrenheit), tin is easily melted and cast into various shapes, making it an ideal metal for casting and soldering applications. This low melting point also allows tin to be used in the production of pewter, a popular alloy composed mainly of tin with small amounts of other metals.

Tin is highly malleable, meaning it can be easily bent, shaped, and formed without breaking. It exhibits a low tendency to fracture, making it suitable for applications that require flexibility and adaptability. Tin’s malleability allows it to be rolled into thin sheets, drawn into wires, or shaped into intricate designs.

Corrosion resistance is another notable property of tin. It forms a thin, protective oxide layer on its surface, which helps prevent further oxidation and corrosion. This corrosion resistance makes tin a valuable material for coatings and plating applications, where it provides a protective layer on other metals, such as steel or copper, to enhance their durability and appearance.

Applications

Tin-plated steel is widely used in the production of food and beverage cans. The thin layer of tin on the steel surface protects the contents from corrosion, maintains food quality, and provides an appealing appearance.

Tin is a key component of many solder alloys due to its low melting point and excellent wetting properties. It is commonly used in electronics assembly, plumbing, and various metalwork applications to create strong and reliable connections.

Tin is used as an alloying element in the production of various alloys. Tin-copper alloys, such as bronze and gunmetal, are known for their strength, corrosion resistance, and casting properties. Tin is also used in the production of Babbitt metal, a tin-based alloy used as a bearing material.

Tin’s corrosion resistance and aesthetic appeal make it suitable for decorative coatings and plating applications. It is used for plating various objects, including jewelry, metal parts, and household items, to improve their appearance and protect against corrosion.

Tin is utilized in certain alloys to prevent the occurrence of tin pest, a phenomenon where tin undergoes a transformation and becomes brittle at low temperatures. The addition of small amounts of other metals, such as antimony or bismuth, helps stabilize the crystal structure of tin and prevents tin pest formation.

Tin is commonly used in electronic components and circuit boards. It serves as a protective coating on copper traces and as a solderable surface for component attachment.

Tin compounds find applications in various chemical processes and industries. For example, tin (II) chloride is used as a reducing agent, and organotin compounds are used as catalysts and stabilizers in chemical reactions.

Titanium

Titanium is a remarkable metallic element known for its exceptional strength, light weight, and excellent corrosion resistance.

The unique properties of titanium, including its strength, light weight, corrosion resistance, biocompatibility, and heat resistance, have made it a valuable material across a wide range of industries. Its versatility and ability to perform in demanding environments contribute to its widespread use in critical applications.

One of the most outstanding features of titanium is its high strength-to-weight ratio. It is about 45% lighter than steel but possesses comparable strength.

This lightweight nature makes titanium a preferred choice in applications where weight reduction is critical, such as aerospace, automotive, and sports equipment manufacturing.

Titanium also exhibits excellent corrosion resistance, even in harsh environments. It forms a thin oxide layer on its surface, called a passivation layer, which provides protection against corrosion from air, water, and many chemicals. This corrosion resistance makes titanium highly suitable for applications in marine environments, chemical processing, and biomedical implants.

Another remarkable property of titanium is its biocompatibility. It is considered a bio-inert material, meaning it does not react with the human body or cause adverse reactions. This biocompatibility, along with its corrosion resistance and strength, makes titanium an ideal choice for medical and dental implants, such as joint replacements, bone plates, and dental fixtures.

Titanium is also highly heat resistant. It has a melting point of 1,668 degrees Celsius (3,034 degrees Fahrenheit) and can withstand high temperatures without significant deformation or loss of strength. This heat resistance makes titanium valuable in applications involving high-temperature environments, including aircraft engines, power generation, and chemical processing equipment.

Additionally, titanium exhibits excellent resistance to fatigue, meaning it can withstand repeated loading and cyclic stresses without failure. This fatigue resistance makes titanium suitable for applications where durability and longevity are crucial, such as in structural components, springs, and prosthetics.

Applications

Titanium is extensively used in aerospace applications due to its high strength, light weight, and corrosion resistance. It is used in aircraft frames, wings, landing gears, turbine blades, and other critical components.

Titanium’s resistance to corrosion makes it valuable in the chemical industry. It is used for equipment such as heat exchangers, reactors, tanks, and piping systems that handle corrosive chemicals.

Titanium’s biocompatibility and corrosion resistance make it an ideal material for medical implants, including joint replacements, dental implants, pacemaker cases, and surgical instruments.

Titanium is used in sporting equipment where lightweight strength is crucial, such as bicycle frames, golf clubs, tennis rackets, and diving equipment.

Titanium’s aesthetic appeal, along with its corrosion resistance, makes it a popular choice in architectural applications. It is used for cladding, roofing, and decorative elements in buildings and structures.

Titanium’s corrosion resistance makes it suitable for marine applications. It is used in shipbuilding, offshore structures, propellers, and seawater desalination systems.

Titanium finds use in high-performance vehicles for components like exhaust systems, valves, and suspension springs, where its lightweight and high strength are advantageous.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

Gun Metals

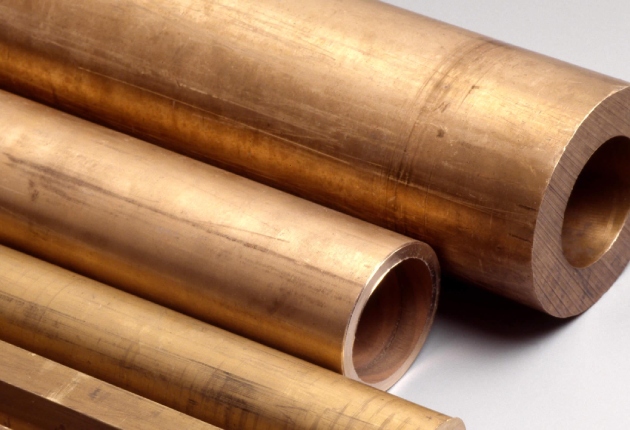

Gunmetal is a type of bronze alloy that is primarily composed of copper, tin, and a small amount of zinc. It is a dense and strong material known for its durability, resistance to wear, and attractive appearance. Gunmetal gets its name from its historical use in the production of firearms and cannons.

The exact composition of gunmetal can vary, but it typically consists of approximately 88% copper, 10% tin, and 2% zinc. This composition gives gunmetal its distinctive dark gray or bluish-gray color, which resembles the appearance of a gun barrel.

One of the key properties of gunmetal is its exceptional strength and hardness. It is harder than pure copper and exhibits good mechanical properties, making it suitable for applications that require resistance to wear, abrasion, and high pressures. Gunmetal’s strength and durability make it a favored material in manufacturing components subjected to heavy loads, such as gears, bearings, valves, and bushings.

Gunmetal also possesses excellent corrosion resistance, particularly in marine and saline environments. The presence of tin and zinc in the alloy contributes to its resistance against corrosion, making it suitable for marine hardware, ship fittings, and other applications exposed to water and moisture.

Another notable characteristic of gunmetal is its self-lubricating properties. The presence of tin in the alloy creates a thin layer of tin oxide on the surface, which acts as a solid lubricant. This self-lubricating property reduces friction and wear in applications, enhancing the durability and efficiency of the components.

Gunmetal’s attractive appearance and unique color make it sought after for decorative purposes. It is commonly used in jewelry, decorative accents, and artistic creations. The dark gray hue of gunmetal adds an elegant and sophisticated touch to various design applications.

Applications

Gunmetal is extensively used in the marine sector for fittings, propellers, shafts, and other components that require high strength and resistance to corrosion in saltwater environments.

Gunmetal is utilized in the production of gears, bearings, valve bodies, pump components, and other mechanical parts that require toughness, wear resistance, and high load-bearing capacity.

Gunmetal’s corrosion resistance and strength make it suitable for plumbing applications, such as valves, connectors, and pipe fittings.

Gunmetal is occasionally used in the production of musical instruments, particularly brass instruments like trombones and trumpets, where its strength and tonal qualities are desirable.

Gunmetal’s unique color and appearance make it a favored material for jewelry, sculptures, statues, and other artistic creations.

Bronze

Bronze is a versatile and widely used alloy consisting primarily of copper, tin, and small amounts of other elements such as zinc, aluminum, or nickel. It is an ancient material that has been used by civilizations for thousands of years due to its favorable properties and diverse applications.

The composition of bronze can vary depending on the desired characteristics and specific application. The addition of tin to copper forms the basis of bronze, and the proportions of these two elements determine the properties of the alloy. Other alloying elements are often incorporated to enhance specific features such as strength, hardness, corrosion resistance, or color.

One of the key advantages of bronze is its exceptional strength and durability. It is significantly stronger than copper and exhibits good resistance to wear, corrosion, and fatigue.

Bronze is also known for its excellent machinability. It can be easily cast, molded, and machined into intricate shapes and designs without losing its mechanical properties. This machinability makes bronze a preferred material for artistic sculptures, architectural ornaments, and decorative objects.

The corrosion resistance of bronze depends on its specific composition. Generally, bronze displays good resistance to corrosion, especially in comparison to iron-based alloys. It forms a protective patina on its surface over time, which helps prevent further oxidation and deterioration. Bronze is often utilized in applications exposed to moisture, such as marine hardware, electrical connectors, and plumbing fixtures.

Another notable characteristic of bronze is its thermal and electrical conductivity. It conducts heat and electricity relatively well, making it suitable for applications that require efficient heat transfer or electrical conductivity. Bronze is used in heat exchangers, electrical contacts, musical instruments, and various electrical connectors and terminals.

Applications

Bronze’s aesthetic appeal, durability, and ease of casting make it a popular choice for creating sculptures, statues, and artistic pieces.

Bronze is employed in the manufacturing of gears, bearings, bushings, valves, and other components that require high strength, wear resistance, and self-lubrication properties.

Bronze’s corrosion resistance and strength make it suitable for marine hardware, propellers, ship fittings, and underwater equipment.

Bronze is used in the production of musical instruments such as cymbals, bells, saxophones, and certain parts of brass instruments.

Bronze is utilized in architectural elements, decorative hardware, door handles, window frames, and other structural components that require strength, durability, and an attractive appearance.

Historically, bronze has been used to mint coins and create currency due to its durability and resistance to wear.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

Brass

Brass is a popular alloy composed primarily of copper and zinc, with varying proportions of each element depending on the desired characteristics and application. It is a versatile material known for its distinctive yellowish-gold color, excellent workability, and wide range of applications.

The composition of brass can vary significantly, ranging from around 60% copper and 40% zinc to different ratios depending on specific requirements. The addition of zinc to copper imparts unique properties to the alloy, making it highly suitable for various applications.

One of the key advantages of brass is its excellent workability. It can be easily shaped, formed, and machined into intricate designs and components. Brass exhibits good ductility, allowing it to be stretched, bent, and manipulated without cracking or losing its mechanical properties. Its malleability makes brass an ideal material for applications requiring complex shapes, such as decorative items, musical instruments, and fittings.

Brass possesses good corrosion resistance, particularly in comparison to other metals. The zinc content in brass forms a protective layer on the surface, helping to prevent oxidation and corrosion. However, the corrosion resistance of brass can vary depending on the specific alloy composition and the environment it is exposed to. Brass is commonly used in applications that require resistance to moisture and corrosion, such as plumbing fittings, valves, and electrical connectors.

Another notable characteristic of brass is its attractive appearance. Its warm golden color gives it a visually appealing and decorative quality. Brass is often used in architectural applications, interior design elements, jewelry, and ornamental objects. Its aesthetic appeal, coupled with its workability, makes brass a favored material for artistic creations and decorative purposes.

Brass exhibits good thermal and electrical conductivity. It efficiently conducts heat and electricity, making it suitable for applications that require efficient heat transfer or electrical conductivity. Brass is used in heat exchangers, radiator cores, electrical connectors, and terminals.

The mechanical properties of brass can vary depending on the specific alloy composition. By adjusting the proportion of copper and zinc, different types of brass can be created with varying strengths, hardness, and other mechanical characteristics. This versatility allows brass to be utilized in a wide range of applications, from low-stress decorative items to high-strength components such as valves, gears, and fasteners.

Applications

Brass fittings, valves, and connectors are widely used in plumbing and piping systems due to their corrosion resistance, durability, and ease of installation.

Brass is a favored material for musical instruments, including trumpets, trombones, saxophones, and various percussion instruments, due to its acoustic properties, workability, and attractive appearance.

Brass is used in electrical connectors, terminals, and contacts due to its excellent electrical conductivity and corrosion resistance.

Bronze is used in the production of musical instruments such as cymbals, bells, saxophones, and certain parts of brass instruments.

Bronze is utilized in architectural elements, decorative hardware, door handles, window frames, and other structural components that require strength, durability, and an attractive appearance.

Historically, bronze has been used to mint coins and create currency due to its durability and resistance to wear.

Aluminum

Aluminium, also spelled aluminum, is a lightweight, silvery-white metallic element known for its excellent strength-to-weight ratio, corrosion resistance, and versatility. It is the most abundant metal in the Earth’s crust, making it highly accessible and widely used in various industries.

Aluminium has a low density, approximately one-third that of steel, which makes it exceptionally lightweight. Despite its lightness, aluminium possesses remarkable strength and durability, making it suitable for applications where weight reduction is critical. The combination of its low density and high strength-to-weight ratio makes aluminium a preferred choice in industries such as aerospace, automotive, transportation, and construction.

One of the outstanding properties of aluminium is its remarkable corrosion resistance.

It naturally forms a thin oxide layer on its surface when exposed to oxygen, providing a protective barrier against further corrosion. This inherent corrosion resistance makes aluminium well-suited for applications in marine environments, as well as in corrosive chemical environments.

Aluminium is highly malleable and ductile, meaning it can be easily formed into various shapes and sizes without losing its mechanical properties. It can be rolled into thin sheets, extruded into complex profiles, or cast into intricate shapes. This excellent formability allows aluminium to be used in a wide range of applications, from simple household items to advanced engineering structures.

Additionally, aluminium is an excellent conductor of both heat and electricity. It possesses high thermal conductivity, allowing it to efficiently transfer heat, making it valuable in applications such as heat sinks, radiators, and cookware. Aluminium’s electrical conductivity makes it useful in electrical transmission lines, electrical enclosures, and electronic components.

Aluminium is also highly recyclable, meaning it can be repeatedly melted down and reprocessed without losing its properties. Recycling aluminium consumes only a fraction of the energy required to produce it from raw materials, making it an environmentally sustainable choice. The recycling capability of aluminium contributes to its popularity in sustainable design and circular economy initiatives.

Applications

Aluminium is extensively used in the aerospace industry for aircraft frames, wings, fuselage components, and interior fittings due to its lightweight nature, strength, and corrosion resistance.

Aluminium is used in various automotive applications, including engine components, body panels, wheels, and structural parts, to reduce weight and enhance fuel efficiency.

Aluminium is employed in window frames, doors, roofing systems, cladding, and structural components in buildings due to its strength, corrosion resistance, and aesthetic appeal.

Aluminium foil and containers are widely used for packaging food and beverages due to their lightness, barrier properties, and ability to be easily shaped.

Aluminium is utilized in electrical transmission lines, power cables, electrical enclosures, and conductors due to its high electrical conductivity.

Aluminium is found in a variety of everyday items such as kitchen utensils, household appliances, furniture, and sports equipment due to its lightweight, durability, and corrosion resistance.

Aluminium is used in shipbuilding, offshore structures, and marine components due to its corrosion resistance and lightweight properties.

Grades of Aluminum

- Aluminum Grade 1xxx:

Examples: 1100, 1050

Composition: These grades contain a minimum of 99% aluminum.

Properties: They have excellent corrosion resistance, high thermal and electrical conductivity, and good formability. However, they have relatively low strength.

- Aluminum Grade 2xxx:

Example: 2024

Composition: The primary alloying element is copper, typically around 4-5%.

Properties: This grade offers high strength, good machinability, and reasonable corrosion resistance. However, it is not as corrosion-resistant as other aluminum grades.

- Aluminum Grade 3xxx:

Examples: 3003, 3105

Composition: Manganese is the primary alloying element, usually present in a range of 1-2%.

Properties: These grades offer good formability, moderate strength, and excellent corrosion resistance. They are often used for general-purpose applications such as cooking utensils, heat exchangers, and sheet metal work.

- Aluminum Grade 5xxx:

Examples: 5052, 5083

Composition: The primary alloying element is magnesium, typically around 2-5%.

Properties: This grade offers good corrosion resistance, moderate to high strength, excellent weldability, and formability. It is commonly used in marine environments, architectural structures, and vehicle panels.

- Aluminum Grade 6xxx:

Examples: 6061, 6063

Composition: These grades contain magnesium and silicon as alloying elements.

Properties: They offer a good balance of strength, formability, corrosion resistance, and weldability. Grade 6061 is widely used in structural applications, while grade 6063 is commonly used for architectural extrusions and piping.

- Aluminum Grade 7xxx:

Example: 7075

Composition: The primary alloying element is zinc, usually around 5-6%.

Properties: This grade offers high strength, good fatigue resistance, and excellent machinability. It is commonly used in aerospace and defense applications where high strength-to-weight ratio is critical.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

Stainless Steel

Stainless steel is an alloy of iron with a minimum of 10.5% chromium content by mass. The addition of chromium forms a thin, invisible, and self-healing layer of chromium oxide on the surface, known as the passive layer. This passive layer is what gives stainless steel its remarkable corrosion resistance.

Key Features of Stainless Steel

Corrosion Resistance: Stainless steel is highly resistant to corrosion and rusting in various environments, including water, acids, chemicals, and atmospheric conditions. This makes it suitable for applications where corrosion resistance is critical, such as in marine environments, chemical processing, and food handling.

Durability and Strength: Stainless steel is known for its excellent strength and durability. It offers good mechanical properties, including high tensile strength and impact resistance, making it suitable for structural applications.

Hygienic and Easy to Clean: Stainless steel has a non-porous surface, which makes it resistant to bacterial growth and easy to clean.

It is commonly used in food processing, medical equipment, and sanitary applications where cleanliness and hygiene are essential.

Heat and Fire Resistance: Stainless steel exhibits high heat resistance, making it suitable for high-temperature applications. It can withstand extreme temperatures without losing its structural integrity, making it suitable for use in ovens, heat exchangers, and exhaust systems.

Aesthetic Appeal: Stainless steel is also chosen for its aesthetic qualities. It has a modern, sleek appearance and is available in various finishes, including brushed, polished, and matte, which makes it popular in architectural and decorative applications.

Versatility: Stainless steel comes in different grades and forms, allowing it to be used in a wide range of applications. From household appliances, automotive parts, and construction materials to surgical instruments, cutlery, and aerospace components, stainless steel finds use in diverse industries.

Applications

- Structural components such as beams, columns, and reinforcement bars.

- Building facades, roofing, and cladding.

- Handrails, balustrades, and decorative elements.

- Interior fittings, fixtures, and appliances.

- Food processing equipment, including tanks, conveyors, and mixing vessels.

- Commercial kitchen equipment, such as countertops, sinks, and food preparation surfaces.

- Storage and transportation containers for food and beverages.

- Surgical instruments, implants, and medical devices.

- Hospital equipment, including cabinets, sinks, and storage units.

- Pharmaceutical processing equipment and sterile environments.

- Exhaust systems, mufflers, and catalytic converters.

- Automotive body parts, such as trim, grilles, and decorative accents.

- Aerospace components, including aircraft bodies, engine parts, and interiors.

- Heat exchangers, boilers, and condensers.

- Pipelines and storage tanks for oil, gas, and petrochemicals.

- Power plant equipment, such as turbines, generators, and nuclear components.

- Shipbuilding components, including hulls, propellers, and fittings.

- Offshore oil rigs and platforms.

- Marine equipment and fittings, such as rails, cleats, and portholes.

- Chemical processing equipment, reactors, and storage tanks.

- Piping systems for corrosive fluids.

- Heat exchangers and pressure vessels.

- Water treatment plants and equipment.

- Waste management systems and containers.

- Desalination plants and equipment.

- Kitchen appliances, cookware, and utensils.

- Sinks, faucets, and fixtures.

- Cutlery, flatware, and decorative items.

- Machinery components and tools.

- Conveyor systems and material handling equipment.

- Wire ropes, springs, and fasteners.

Grades of Stainless Steel

- Austenitic Stainless Steel:

Grades: 304, 316, 321, 310, 304L, 316L, 904L, etc.

Characteristics: Austenitic stainless steel is the most widely used type, known for its excellent corrosion resistance, high ductility, and good formability. It is non-magnetic and typically contains nickel (Ni) and chromium (Cr) as the main alloying elements.

- Ferritic Stainless Steel:

Grades: 430, 409, 434, 439, etc.

Characteristics: Ferritic stainless steel has good resistance to corrosion, high-temperature oxidation, and stress corrosion cracking. It possesses lower ductility and toughness compared to austenitic stainless steel. Ferritic grades generally contain chromium as the main alloying element.

- Martensitic Stainless Steel:

Grades: 410, 420, 440C, etc.

Characteristics: Martensitic stainless steel is known for its high strength, hardness, and wear resistance. It has moderate corrosion resistance and can be heat-treated to achieve greater hardness. Martensitic grades contain higher levels of carbon along with chromium.

- Duplex Stainless Steel:

Grades: 2205 (S31803), 2507 (S32750), etc.

Characteristics: Duplex stainless steel offers a combination of high strength and excellent corrosion resistance. It has a two-phase microstructure consisting of both austenite and ferrite. Duplex grades exhibit good resistance to stress corrosion cracking and pitting corrosion.

- Precipitation Hardening Stainless Steel:

Grades: 17-4PH, 15-5PH, etc.

Characteristics: Precipitation hardening stainless steel is characterized by its high strength, excellent corrosion resistance, and the ability to be heat-treated to achieve even higher strength levels. These grades contain alloying elements such as copper, aluminum, and niobium.

- High-temperature Austenitic Stainless Steel:

Grades: 309, 310, 321H, etc.

Characteristics: High-temperature austenitic stainless steel grades are designed to withstand elevated temperatures, typically above 500°C (932°F). They possess excellent oxidation resistance, creep strength, and thermal stability.

Get In Touch!

- Address

RL 15 Bajajnagar MIDC Waluj Aurangabad

- Email Us

- Call Us