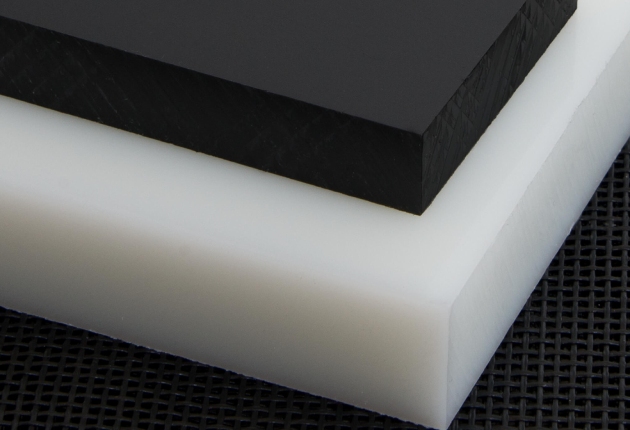

HDPE – High Density Polyethylene

HDPE stands for High-Density Polyethylene, which is a versatile and widely used thermoplastic polymer. It is a type of plastic that is known for its exceptional strength, durability, and resistance to various chemicals and solvents. HDPE is produced through the polymerization of ethylene under high pressure conditions.

Here Are Some Key Characteristics And Features Of HDPE:

Density: HDPE has a high density, hence the name “high-density” polyethylene. It typically has a density ranging from 0.93 to 0.97 g/cm³. The high density contributes to its strength and rigidity.

Strength and Durability: HDPE is a highly robust material with excellent tensile strength and resistance to impact. It can withstand heavy loads, making it suitable for various applications requiring strength and durability.

Chemical Resistance: One of the notable properties of HDPE is its resistance to a wide range of chemicals, including acids, alkalis, and solvents. This resistance makes HDPE suitable for applications in industries such as chemical processing, water treatment, and storage of corrosive substances.

Moisture Resistance: HDPE is inherently moisture-resistant, which makes it suitable for outdoor applications and those involving contact with liquids. It does not absorb water and is resistant to rot, mold, and mildew.

UV Resistance: HDPE has good resistance to ultraviolet (UV) radiation, making it suitable for outdoor applications. It can withstand prolonged exposure to sunlight without significant degradation, making it ideal for applications like outdoor furniture, pipes, and geomembranes.

Flexibility: Although HDPE is a rigid material, it also possesses a certain degree of flexibility. It can be molded or shaped into various forms and can withstand repeated bending without cracking or breaking.

Thermal Stability: HDPE has good thermal stability and can withstand a wide temperature range. It retains its mechanical properties even at elevated temperatures, making it suitable for both hot and cold environments.

Recyclability: HDPE is highly recyclable and can be melted and reprocessed into new products. This recyclability contributes to its environmental sustainability and reduces waste.

Due to its excellent properties, HDPE finds applications in a wide range of industries, including packaging, construction, automotive, agriculture, electrical, and more. Some common applications of HDPE include plastic bottles, pipes, tanks, containers, toys, plastic lumber, geomembranes, and various types of packaging materials.

Applications

Packaging: HDPE is used in a wide variety of packaging applications, including bottles, jugs, tubs, and containers. It is also used in the production of shrink wrap and pallet wrap.

Pipes and fittings: HDPE is a popular material for pipes and fittings because it is strong, durable, and resistant to corrosion. It is used in a variety of applications, including water, gas, and sewer pipes.

Building materials: HDPE is used in a variety of building materials, including lumber, siding, and roofing. It is also used in the production of fencing and other outdoor structures.

Industrial applications: HDPE is used in a variety of industrial applications, including electrical insulation, automotive components, and agricultural equipment.

Medical applications: HDPE is used in a variety of medical applications, including blood bags, IV bags, and surgical tubing. It is also used in the production of medical devices, such as catheters and stents.

Nylon

Nylon is a synthetic thermoplastic polymer known for its exceptional strength, durability, and versatility. Nylon is produced through the polymerization of monomers, most commonly caprolactam or adipic acid.

Here Are The Key Characteristics And Features Of Nylon:

Strength and Durability: Nylon is known for its high strength-to-weight ratio. It possesses excellent tensile strength, making it suitable for applications that require robustness and load-bearing capacity. Nylon is also highly resistant to wear, abrasion, and impact, which contributes to its durability.

Chemical Resistance: Nylon exhibits good resistance to many chemicals, including oils, solvents, and alkaline substances. However, it may be affected by strong acids or certain organic solvents, so compatibility should be considered for specific applications.

Flexibility: Nylon is a flexible material that can be easily molded or shaped into various forms. It has a high elongation at break, which means it can withstand bending and stretching without breaking.

This flexibility makes nylon suitable for applications requiring parts with intricate designs or those that need to be molded into complex shapes.

Moisture Absorption: Nylon has a moderate level of moisture absorption, which can affect its mechanical properties. It absorbs and desorbs moisture, leading to dimensional changes in certain conditions. This property should be considered in applications where dimensional stability is crucial.

Friction and Wear Properties: Nylon has excellent friction and wear characteristics. It exhibits low friction against other materials, making it suitable for applications such as bearings, gears, and wear-resistant components. Additionally, nylon’s self-lubricating properties can reduce the need for additional lubrication.

Temperature Resistance: Nylon has a relatively high melting point, typically between 210°C to 280°C (410°F to 536°F), depending on the type and grade. It retains its mechanical properties at elevated temperatures, making it suitable for applications involving heat or friction.

Cast Nylon, also known as Cast Polyamide, is a specific type of nylon produced through a casting process. It offers several additional advantages compared to standard nylon:

Improved Mechanical Properties: Cast Nylon has enhanced mechanical properties, including higher strength and toughness compared to traditional nylon. It exhibits lower water absorption, better dimensional stability, and improved wear resistance.

Size and Shape Flexibility: The casting process allows for the production of large-sized and custom-shaped parts. Complex geometries, such as gears, rollers, and bushings, can be manufactured with precise dimensions and tight tolerances.

Self-Lubrication: Cast Nylon can be formulated with additives to improve its self-lubricating properties, reducing friction and wear in applications without external lubrication. This makes it suitable for components subjected to sliding or rotating motions.

Both nylon and cast nylon find applications in numerous industries, including automotive, aerospace, electrical, textiles, consumer goods, and industrial manufacturing. Some common applications include gears, bearings, bushings, rollers, seals, conveyor belts, electrical connectors, textile fibers, and various structural components.

Applications

Textiles: Nylon is a popular material for textiles because it is strong, durable, and wrinkle-resistant. It is used in a variety of garments, including hosiery, underwear, and outerwear.

Fibers: Nylon fibers are used in a variety of products, including ropes, carpets, and fishing line. They are also used in some medical applications, such as sutures and surgical mesh.

Molding: Nylon is a popular material for molding because it is strong, durable, and can be easily molded into a variety of shapes. It is used in a variety of products, including gears, bearings, and housings.

Injection molding: Nylon is a common material for injection molding because it is strong, durable, and can be easily molded into a variety of shapes. It is used in a variety of products, including gears, bearings, and housings.

3D printing: Nylon is a popular material for 3D printing because it is strong, durable, and can be easily printed into a variety of shapes. It is used in a variety of products, including prototypes, models, and end-use parts.

Nylon is a safe material for most people to use. However, some people may experience allergic reactions to nylon. If you have concerns about using nylon, talk to your doctor.

Automotive: Nylon is used in a variety of automotive applications, including gears, bearings, and hoses.

Electrical: Nylon is used in a variety of electrical applications, including insulators, connectors, and switches.

Medical: Nylon is used in a variety of medical applications, including sutures, surgical mesh, and implants.

Sports: Nylon is used in a variety of sports equipment, including rackets, golf clubs, and fishing rods.

Industrial: Nylon is used in a variety of industrial applications, including conveyor belts, hoses, and gears.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

PU (Polyurethane)

Polyurethane (PU) is a versatile and widely used synthetic material that belongs to the class of polymers known as elastomers. It is formed through the reaction of polyols (a type of alcohol) with diisocyanates (a type of chemical compound).

Here Are the Key Characteristics and Features of Polyurethane (PU):

Flexibility and Elasticity: Polyurethane exhibits excellent flexibility and elasticity, allowing it to stretch and recover its original shape. It offers superior resilience compared to many other materials, making it suitable for applications that require cushioning or impact absorption.

High Abrasion Resistance: PU has excellent resistance to abrasion, wear, and tear. It can withstand heavy use and repetitive stresses, making it suitable for applications that involve friction or contact with rough surfaces.

Wide Hardness Range: Polyurethane can be formulated to achieve a wide range of hardness levels, from very soft and flexible to rigid and stiff. This versatility allows it to be used in various applications where different levels of hardness are required.

Chemical Resistance: PU exhibits good resistance to oils, greases, solvents, and many chemicals. It can withstand exposure to a range of substances without significant degradation, making it suitable for applications in industries such as automotive, construction, and manufacturing.

Excellent Load-Bearing Capacity: Polyurethane has high load-bearing capacity and can withstand heavy loads without permanent deformation. It is commonly used in load-bearing components such as wheels, bushings, and industrial machinery parts.

Thermal Stability: PU exhibits good thermal stability, maintaining its mechanical properties across a wide range of temperatures. It can withstand both high and low temperatures, making it suitable for applications in diverse environments.

Water and Moisture Resistance: Polyurethane has inherent resistance to water and moisture, making it suitable for applications exposed to wet conditions. It does not absorb water easily and maintains its properties even when exposed to humid environments.

Wide Range of Applications: Polyurethane finds applications in various industries, including automotive, construction, furniture, footwear, sports equipment, electronics, and more. It is used in products such as foam cushions, insulation, adhesives, coatings, seals, gaskets, wheels, and flexible or rigid molded parts.

Applications

Foam: PU foam is a popular material for foam because it is soft, comfortable, and can be easily molded into a variety of shapes. It is used in a variety of products, including mattresses, pillows, and furniture cushions.

Elastomers: PU elastomers are used in a variety of products, including tires, seals, and gaskets. They are also used in some medical applications, such as artificial joints.

Coatings: PU coatings are used in a variety of products, including paints, adhesives, and sealants. They are also used in some industrial applications, such as corrosion protection.

Molding: PU is a popular material for molding because it is strong, durable, and can be easily molded into a variety of shapes. It is used in a variety of products, including gears, bearings, and housings.

Injection molding: PU is a common material for injection molding because it is strong, durable, and can be easily molded into a variety of shapes. It is used in a variety of products, including gears, bearings, and housings.

3D printing: PU is a popular material for 3D printing because it is strong, durable, and can be easily printed into a variety of shapes. It is used in a variety of products, including prototypes, models, and end-use parts.

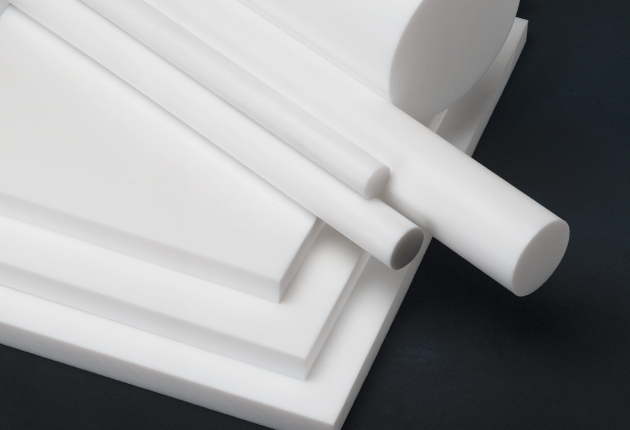

Teflon / PTFE

Teflon, also known as PTFE (Polytetrafluoroethylene), is a synthetic fluoropolymer that is widely recognized for its exceptional nonstick and heat-resistant properties.

Here Are the Key Characteristics and Features of Teflon/PTFE:

Nonstick Properties: Teflon/PTFE has one of its most well-known properties—excellent nonstick characteristics. It has an extremely low coefficient of friction, which means that substances have a reduced tendency to stick to its surface. This property makes Teflon/PTFE ideal for use in cookware, where food particles can easily be released from the surface without sticking.

Heat Resistance: Teflon/PTFE is highly heat-resistant and can withstand a wide temperature range without significant degradation. It has a melting point of approximately 327°C (621°F) and can maintain its properties at high temperatures. This heat resistance makes it suitable for applications in cooking, industrial processing, and electrical insulation.

Chemical Resistance: Teflon/PTFE exhibits excellent resistance to a wide range of chemicals, including acids, bases, solvents, and corrosive substances. It is known to be chemically inert, which means it does not react with most chemicals. This resistance makes it highly valuable in chemical processing, oil and gas, and laboratory equipment applications.

Low Friction and Wear Resistance: Teflon/PTFE has outstanding low-friction properties, reducing the amount of wear and tear on surfaces that come into contact with it. It exhibits excellent lubricity, which helps minimize friction and extends the lifespan of moving parts. This property makes it suitable for use in bearings, seals, slide plates, and other applications requiring low friction.

Electrical Insulation: Teflon/PTFE is an excellent electrical insulator, providing high dielectric strength and low electrical conductivity. It is widely used in electrical and electronic applications, including wiring insulation, cable connectors, circuit boards, and other components that require insulation from electric current.

Weather and UV Resistance: Teflon/PTFE is highly resistant to weathering and UV radiation. It does not degrade or deteriorate significantly when exposed to sunlight or outdoor elements, making it suitable for outdoor applications such as architectural coatings, roofing membranes, and outdoor equipment.

Low Surface Energy: Teflon/PTFE has a low surface energy, which means it has excellent water and oil repellency. Liquids tend to bead up and roll off its surface, contributing to its nonstick properties. This characteristic is beneficial in applications that require resistance to liquid absorption or where easy cleaning is essential.

Due to its unique combination of properties, Teflon/PTFE finds applications in various industries, including food processing, automotive, chemical, electrical, telecommunications, and aerospace. It is used in products such as nonstick cookware, gaskets, seals, bearings, electrical insulation, pipes and tubing, valve components, and coatings for various surfaces.

Applications

Cookware: Teflon is the most common coating for non-stick cookware. Its non-stick properties make it easy to cook food without sticking, and its low-friction properties make it easy to clean.

Medical devices: Teflon is used in a variety of medical devices, such as heart valves, artificial joints, and catheters. Its chemical resistance makes it ideal for use in these applications, as it is not affected by body fluids or chemicals.

Industrial applications: Teflon is used in a variety of industrial applications, such as gaskets, seals, and bearings. Its chemical resistance and low-friction properties make it ideal for use in these applications.

Electrical applications: Teflon is used in a variety of electrical applications, such as insulators, connectors, and switches. Its high dielectric strength and low-friction properties make it ideal for use in these applications.

Other applications: Teflon is also used in a variety of other applications, such as fabric finishing, carpeting, and rainwear. Its non-stick, low-friction, and chemical-resistant characteristics make it a valuable material for these applications.

Teflon is a safe material for most people to use. However, some people may experience allergic reactions to Teflon. If you have concerns about using Teflon, talk to your doctor.

Film: Teflon film is used in a variety of applications, including food packaging, electrical insulation, and medical devices.

Coatings: Teflon coatings are used in a variety of applications, including cookware, medical devices, and industrial equipment.

Fibers: Teflon fibers are used in a variety of applications, including fabrics, carpets, and composites.

Additives: Teflon additives are used in a variety of applications, including plastics, rubber, and paints.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

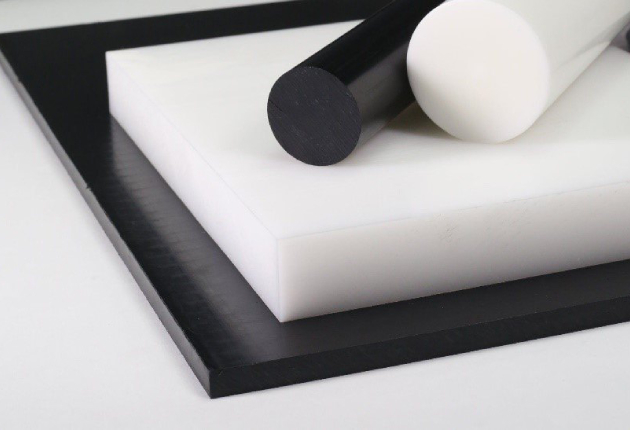

Derlin / POM

Delrin (also known as POM, polyoxymethylene) is an engineering thermoplastic with a high degree of strength, stiffness, and dimensional stability. It is a semi-crystalline material that is available in a variety of grades, including homopolymer, copolymer, and filled grades.

Delrin has a number of key properties that make it a valuable material for a wide range of applications. These properties include:

High strength and stiffness: Delrin is a very strong and stiff material, with a tensile strength of up to 11,000 psi and a flexural modulus of up to 200,000 psi. This makes it ideal for applications where high strength and stiffness are required, such as gears, bearings, and bushings.

Dimensional stability: Delrin is very dimensionally stable, with a low coefficient of thermal expansion. This means that it will not warp or deform when exposed to changes in temperature or humidity. This makes it ideal for applications where precise dimensional tolerances are required, such as medical devices and precision instruments.

Low friction: Delrin has a low coefficient of friction, making it a good choice for applications where sliding or rolling contact is required.

This makes it ideal for bearings, gears, and other components that need to operate smoothly and efficiently.

Chemical resistance: Delrin is resistant to a wide range of chemicals, including acids, bases, and solvents. This makes it ideal for applications where exposure to chemicals is likely, such as food processing and chemical manufacturing.

Ease of machining: Delrin is easy to machine, making it a good choice for applications where complex parts are required.

Delrin is a versatile material with a wide range of applications. It is used in a variety of industries, including automotive, aerospace, medical, and electrical. Some common applications for Delrin include:

Gears, Bearings, Bushings, Rollers, Pumps, Valves, Electrical components, medical devices, Sporting goods, Toys.

Applications

Automotive: Derlin is used in a variety of automotive applications, including gears, bearings, and housings.

Appliances: Derlin is used in a variety of appliance applications, including dishwashers, washing machines, and refrigerators.

Construction: Derlin is used in a variety of construction applications, including window frames, door frames, and railings.

Medical: Derlin is used in a variety of medical applications, including surgical instruments and implants.

Industrial: Derlin is used in a variety of industrial applications, including bearings, gears, and pumps.

Blacklite /Hylam

Blacklite, also known as Hylam, is a type of industrial laminate material that is widely used for its excellent electrical insulation properties and mechanical strength. It is a composite material composed of layers of fabric or paper impregnated with phenolic resin, which is then subjected to high pressure and heat to create a solid and durable sheet.

Blacklite/Hylam is known for its exceptional electrical insulation capabilities, making it highly sought after in electrical and electronic applications. It has a high dielectric strength, which means it can withstand high voltages without electrically conducting or breaking down.

This property makes it ideal for use in insulating electrical components, such as switchgear, transformers, electrical panels, and circuit boards.

Another key characteristic of Blacklite/Hylam is its mechanical strength. It exhibits high tensile and compressive strength, providing excellent load-bearing capacity and resistance to mechanical stress. This makes it suitable for applications requiring structural integrity, such as in machine parts, gears, bushings, and structural supports.

Blacklite/Hylam also offers good dimensional stability, meaning it retains its shape and dimensions even under varying temperature and humidity conditions. This property is essential in maintaining the accuracy and functionality of components over time, especially in precision equipment and tools.

Additionally, Blacklite/Hylam has good chemical resistance to a wide range of solvents, oils, and fuels. It is resistant to moisture absorption, which helps prevent swelling or warping of the material when exposed to humid environments. This resistance to chemicals and moisture makes it suitable for applications in challenging and corrosive environments.

Furthermore, Blacklite/Hylam is relatively easy to machine and fabricate. It can be cut, drilled, milled, and turned into various shapes and sizes, allowing for customization and versatility in manufacturing processes.

Applications

Blacklite/Hylam has a wide range of applications across various industries due to its excellent electrical insulation properties, mechanical strength, and dimensional stability. Some common applications of Blacklite/Hylam include:

Electrical and Electronics Industry: Blacklite/Hylam is extensively used in electrical and electronic components where high electrical insulation is required. It is used for insulation in switchgear, transformers, electrical panels, circuit boards, insulating washers, and terminal blocks.

Mechanical Engineering: Blacklite/Hylam finds applications in mechanical engineering due to its high mechanical strength and durability.

It is used for manufacturing gears, bushings, bearings, wear strips, pulleys, rollers, and other machine components that require excellent load-bearing capacity and resistance to wear.

Automotive Industry: Blacklite/Hylam is used in the automotive industry for various applications. It is employed in the manufacturing of electrical connectors, insulating parts for ignition systems, distributor caps, gaskets, and other components requiring electrical insulation and mechanical stability.

Aerospace Industry: In the aerospace sector, Blacklite/Hylam is utilized for its electrical insulation properties and resistance to high temperatures. It is used in aircraft components such as electrical connectors, insulators, control panels, and thermal barriers.

Construction Industry: Blacklite/Hylam is used in the construction industry for applications that require mechanical strength, dimensional stability, and resistance to moisture and chemicals. It finds use in manufacturing composite panels, insulation boards, wall claddings, and structural components.

Marine Industry: Due to its resistance to moisture, chemicals, and dimensional stability, Blacklite/Hylam is employed in marine applications. It is used for manufacturing electrical components, insulating materials, bearings, gears, and other parts in boats, ships, and marine equipment.

Industrial Equipment: Blacklite/Hylam is utilized in various industrial equipment and machinery. It is used for manufacturing rollers, guides, pulleys, wear plates, insulating spacers, and other components requiring high mechanical strength and resistance to wear.

Tooling and Jigs: Blacklite/Hylam is also used in tooling and jigs due to its machinability and durability. It is employed for creating fixtures, cutting dies, templates, and other tooling components.

Looking for the Best Non-Ferrous Metal?

Shree Engineering Suppliers is Your One Stop Solutions.

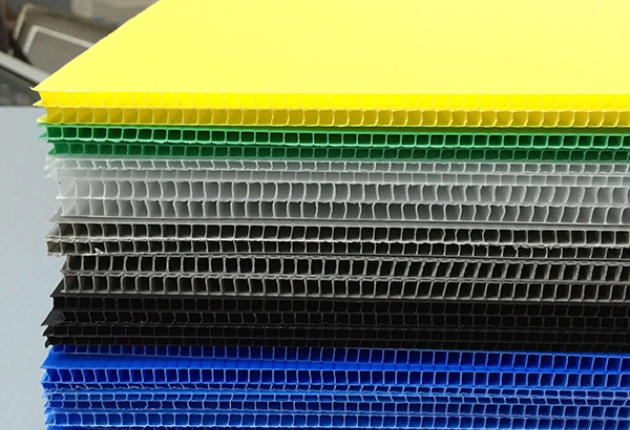

Corrugated Plastic

Corrugated plastic, also known as coroplast, is a lightweight and durable plastic material that is commonly used in various industries for packaging, signage, and other applications. It is made from polypropylene, a thermoplastic polymer known for its excellent strength and chemical resistance.

The distinctive feature of corrugated plastic is its structure, which consists of two flat plastic sheets with a series of parallel flutes or ridges running between them. These flutes provide added strength and rigidity to the material while maintaining its lightweight properties. The flutes also create air pockets, enhancing the material’s insulation capabilities.

Corrugated plastic is highly versatile and offers numerous advantages. Firstly, it is resistant to moisture, chemicals, and most solvents, making it suitable for outdoor use and harsh environments.

Additionally, it is UV-resistant, ensuring its durability and color retention even when exposed to sunlight. The material is also easy to clean and maintain.

Due to its lightweight nature, corrugated plastic is easy to handle and transport. It can be easily cut, shaped, and fabricated into various forms such as sheets, boxes, containers, and displays. The material is also printable, allowing for customized designs, logos, and information to be added through screen printing or digital printing methods.

Corrugated plastic finds widespread use in packaging applications, particularly for transporting and protecting goods during shipping. It is commonly used for making boxes, dividers, and inserts to securely hold products in place. The material’s impact resistance and cushioning properties help safeguard items from damage.

In the advertising and signage industry, corrugated plastic is often utilized for creating temporary or semi-permanent displays, banners, and signs. Its lightweight nature allows for easy installation and portability, making it suitable for events, exhibitions, and outdoor advertising.

Key Properties Of Corrugated Plastic

Corrugated plastic is lightweight, making it easy to transport and handle.

Corrugated plastic is strong and durable, making it resistant to impact and bending.

Corrugated plastic is durable and can withstand a wide range of environmental conditions, including heat, cold, moisture, and chemicals.

Corrugated plastic is resistant to a wide range of chemicals, making it ideal for use in applications where exposure to chemicals is likely.

Corrugated plastic is water-resistant, making it ideal for use in outdoor applications.

Corrugated plastic is UV-resistant, making it ideal for use in applications where exposure to sunlight is likely.

Corrugated plastic is printable, making it ideal for use in applications where custom graphics are required.

Applications

Signage: Corrugated plastic is often used to make signs because it is lightweight, durable, and can be easily printed on.

Packaging: Corrugated plastic is a popular material for packaging because it is lightweight, strong, and can be easily molded to fit different shapes and sizes.

Building materials: Corrugated plastic is sometimes used as a building material, such as for roofing or siding.

Industrial applications: Corrugated plastic is used in a variety of industrial applications, such as for conveyor belts, guards, and covers.

Get In Touch!

- Address

RL 15 Bajajnagar MIDC Waluj Aurangabad

- Email Us

- Call Us